Top Quality Wear Parts for Industrial Machinery

By:Admin

Founded in 2008, C and S Wear Parts has grown steadily over the years, establishing a reputation for delivering durable and reliable wear parts for a wide range of equipment. The company's products are known for their high performance and long lifespan, making them a top choice for customers in the construction and mining sectors.

The recent announcement from C and S Wear Parts is regarding their expansion into new territories. The company has successfully secured partnerships with several new distributors, allowing them to reach customers in previously untapped markets. This expansion represents a significant achievement for C and S Wear Parts, as it demonstrates the company's commitment to growth and serving a wider customer base.

"We are thrilled to announce our expansion into new territories," said the CEO of C and S Wear Parts. "This development is a testament to the hard work and dedication of our team, as well as the quality and reliability of our products. We are confident that our new partnerships will allow us to better serve our customers and meet the growing demand for our wear parts."

In addition to expanding into new territories, C and S Wear Parts has also invested in upgrading their manufacturing processes and technologies. This investment is aimed at increasing production capacity and improving the efficiency of their operations. By modernizing their facilities and adopting the latest manufacturing techniques, C and S Wear Parts is poised to meet the increasing demand for their products while maintaining their high standards of quality.

Furthermore, the company has also focused on expanding their product range to better meet the diverse needs of their customers. In addition to their existing line of wear parts, C and S Wear Parts has introduced new products that are specifically designed for emerging trends in the construction and mining industries. These new offerings are the result of extensive research and development, and they underscore the company's commitment to innovation and staying ahead of the market.

"The expansion of our product range is a strategic move to cater to the evolving needs of our customers," the CEO remarked. "We have listened to the feedback from the market and have responded with new, cutting-edge products that will help our customers achieve greater efficiency and productivity in their operations. We are excited to bring these new offerings to the market and continue to be a trusted partner for our customers."

Ultimately, the recent developments at C and S Wear Parts signal a new chapter of growth and success for the company. By expanding into new territories, investing in modernizing their manufacturing processes, and introducing new products, the company is positioning itself for long-term success and excellence in the wear parts industry. With a strong track record and a forward-looking approach, C and S Wear Parts is poised to continue leading the market and exceeding the expectations of their customers.

Company News & Blog

Advanced Casting Process in China: Squeeze Casting Revolutionizes Manufacturing

Title: Advanced Squeeze Casting Process Revolutionizes Manufacturing in ChinaIntroduction [Company Name]: [Company Name] is a renowned leader in the field of casting technology, based in China. With a strong focus on innovation and research, the company has gained international recognition for its cutting-edge manufacturing processes.[Company Name]'s commitment to technological advancement is exemplified by its latest breakthrough, the China Squeeze Casting Process. This state-of-the-art process revolutionizes the manufacturing industry by combining the benefits of traditional casting techniques with the efficiency and precision of advanced squeezing technology.Body:1. Overview of Squeeze Casting Process:The Squeeze Casting Process is a revolutionary manufacturing technique that combines the features of both casting and forging. This process involves pouring molten metal into a preheated die, followed by applying high pressure to the metal until it solidifies. This simultaneous casting and squeezing process results in high-density, near-net-shape components with superior mechanical properties.2. The Advantages of Squeeze Casting:The China Squeeze Casting Process presents numerous advantages over conventional manufacturing techniques, such as die casting or forging:- Enhanced Mechanical Properties: The application of high pressure during squeeze casting ensures a dense, uniform microstructure, significantly enhancing the mechanical properties of the final product. This leads to increased strength, improved fatigue resistance, and better dimensional stability.- Near-net-shape Components: Squeeze casting allows for the production of near-net-shape components, reducing the need for subsequent machining and reducing material waste. This results in cost savings and shorter production cycles.- Versatility of Material Selection: Squeeze casting is compatible with a wide range of materials, including aluminum, magnesium, copper alloys, and even certain steels. The process enables the production of lightweight, high-performance components for various industries.3. Industry Applications:The China Squeeze Casting Process finds diverse applications in several industries:- Automotive: Squeeze casting enables the production of lightweight, high-strength components for automotive applications, improving fuel efficiency and overall performance. Engine blocks, pistons, crankshafts, and suspension components are just a few examples.- Aerospace: The exceptional mechanical properties achieved through squeeze casting make it ideal for aerospace applications. Components like turbine blades, structural parts, and landing gear benefit from improved strength and durability, ensuring safety and reliability.- Electronics: With the growing demand for smaller, lighter, and more efficient electronic devices, squeeze casting provides excellent opportunities. The process can produce intricate, heat-dissipating components for smartphones, laptops, and other electronic devices.4. [Company Name]: A Leader in Squeeze Casting Technology:[Company Name] has been at the forefront of developing and implementing the China Squeeze Casting Process. With a dedicated team of engineers and state-of-the-art facilities, the company has successfully collaborated with various industries in utilizing this groundbreaking technology.The company's in-depth knowledge and expertise in squeeze casting has resulted in numerous success stories and satisfied clients worldwide. By partnering with [Company Name], businesses gain access to a wealth of experience, cutting-edge technology, and exceptional quality control.Conclusion:The China Squeeze Casting Process, pioneered by [Company Name], represents a significant leap forward in the manufacturing industry. With its ability to produce near-net-shape components with enhanced mechanical properties, this breakthrough technology provides endless possibilities for various sectors, including automotive, aerospace, and electronics.As [Company Name] continues to push the boundaries of technological innovation, their commitment to delivering superior products and solutions further solidifies their position as a leader in the casting industry.

Top Quality Heavy Duty Bulldozer Spare Parts for Sale

The heavy-duty equipment industry is a vital part of the global economy, providing essential machinery and parts for construction, mining, and other industrial operations. One company that has been a leading provider of heavy-duty equipment and spare parts is {}. Specializing in a wide range of heavy-duty equipment and machinery, {} has been a trusted name in the industry for decades.One of the key products that {} has become renowned for is its range of spare parts for heavy-duty equipment, particularly for its line of CAT bulldozers. The CAT bulldozer is widely recognized as a powerhouse in the construction and mining sectors, known for its durability, power, and efficiency. However, like all heavy-duty equipment, CAT bulldozers require regular maintenance and occasional replacement of parts to ensure optimal performance.This is where {} comes in. With a comprehensive inventory of CAT bulldozer spare parts, {} is able to provide customers with the parts they need to keep their equipment running smoothly and efficiently. Whether it's a new set of tracks, a replacement engine component, or a specialized attachment, {} has the expertise and resources to supply the right parts for any CAT bulldozer model.In addition to spare parts, {} also offers a range of other heavy-duty equipment products, including excavators, wheel loaders, and motor graders. With a focus on quality, reliability, and customer satisfaction, {} has built a strong reputation as a go-to source for all heavy-duty equipment needs.The company employs a team of highly skilled and experienced professionals who are dedicated to providing exceptional service and support to customers. From assisting with product selection to offering technical guidance and after-sales support, {} strives to ensure that each customer receives the personalized attention and care they deserve.Furthermore, {} is committed to staying at the forefront of the industry, constantly adapting to new technologies and innovations to better serve its customers. By staying ahead of industry trends and advancements, {} can continue to provide cutting-edge solutions for heavy-duty equipment needs.As part of its commitment to excellence, {} also emphasizes environmental sustainability and safety in its operations. The company adheres to strict environmental standards and regulations, and is continually seeking ways to minimize its ecological footprint and promote a safe working environment for its employees and customers.In conclusion, {} is a leading provider of heavy-duty equipment and spare parts, with a strong focus on quality, reliability, and customer satisfaction. With a comprehensive inventory of CAT bulldozer spare parts and a dedicated team of professionals, {} is well-equipped to meet the diverse needs of its customers in the construction, mining, and industrial sectors. Whether it's supplying spare parts, offering technical support, or staying ahead of industry trends, {} is dedicated to being a trusted partner for all heavy-duty equipment needs.

High-Quality Bulldozer Undercarriage Parts for Heavy Equipment

A leading construction equipment company has recently introduced a new line of undercarriage parts for the popular Caterpillar D10 bulldozer. With a focus on durability and efficiency, these parts are poised to revolutionize the way heavy machinery operates in the field.The company, known for its high-quality construction equipment and parts, has been a key player in the industry for over a decade. Their dedication to excellence and customer satisfaction has earned them a solid reputation among construction professionals.The new undercarriage parts for the Caterpillar D10 bulldozer are a result of extensive research and development. Engineers and designers worked tirelessly to create a product that would not only meet but exceed industry standards. The parts have been rigorously tested to ensure they can withstand the toughest working conditions, from rocky terrain to muddy construction sites.One of the key features of these undercarriage parts is their ability to reduce downtime. With easy installation and minimal maintenance requirements, construction crews can spend less time on repairs and more time on the job. This is a game-changer for companies looking to maximize their productivity and efficiency.In addition to their durability and ease of use, these undercarriage parts also boast improved performance capabilities. Enhanced traction and stability mean that the Caterpillar D10 bulldozer can handle heavier loads and navigate challenging landscapes with ease. This not only increases the machine's versatility but also provides a safer working environment for the operators.Furthermore, the company's commitment to sustainability is evident in these new undercarriage parts. By optimizing fuel efficiency and reducing emissions, the parts are not only beneficial for the environment but also for the bottom line of construction companies. This aligns with the industry's growing demand for eco-friendly solutions that do not compromise on performance.The introduction of these undercarriage parts is a testament to the company's ongoing dedication to innovation and customer satisfaction. By continually pushing the boundaries of what is possible in construction equipment, they have solidified their position as a leader in the industry.Construction professionals have already expressed their excitement about the new undercarriage parts for the Caterpillar D10 bulldozer. Many have recognized the potential for increased productivity and cost savings, which are critical in today's competitive market. With these parts, companies can expect to see a significant return on investment in the form of improved efficiency and extended equipment lifespan.As the construction industry continues to evolve, the demand for high-quality, reliable equipment and parts will only continue to grow. The introduction of these undercarriage parts serves as a reminder that innovation is essential for staying ahead of the curve. With a focus on durability, efficiency, and sustainability, the company has set a new standard for construction equipment and is well-positioned to meet the needs of the industry for years to come.In conclusion, the new line of undercarriage parts for the Caterpillar D10 bulldozer represents a significant advancement in construction equipment technology. With a focus on durability, efficiency, and sustainability, these parts are poised to revolutionize the way heavy machinery operates in the field. The company's commitment to innovation and customer satisfaction has once again been demonstrated, solidifying their position as a leader in the industry. Construction professionals can look forward to increased productivity, cost savings, and a reduced environmental impact with these new undercarriage parts.

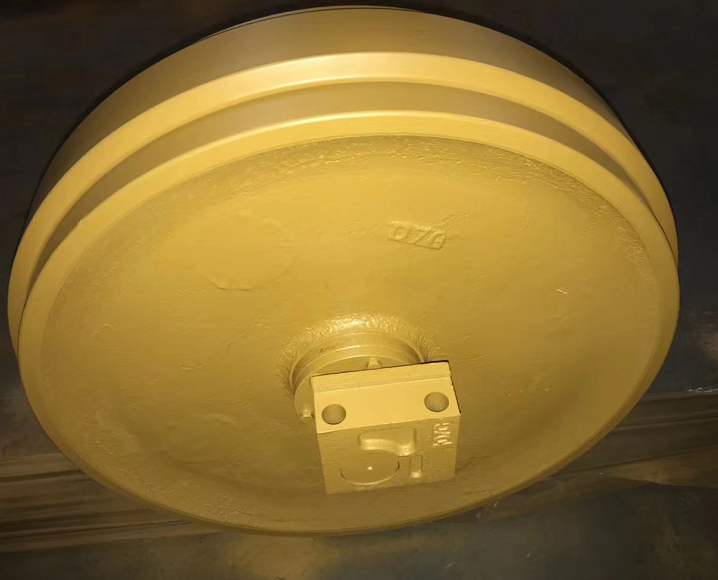

Heavy Duty Bottom Roller Exporter and Heavy Wheel OEM Factory in Dubai at Competitive Prices

Dh55, D375 Bottom Roller Exporter, and D375 Heavy Wheel OEM Factory Expand to Meet Growing DemandIn response to the increasing demand for heavy machinery and construction equipment in the global market, {Company Name} is expanding its export capabilities for Dh55 and D375 bottom rollers, as well as its production capacity for D375 heavy wheels. With a commitment to providing high-quality products and exceptional customer service, the company is positioning itself to better serve its clients and continue its growth in the industry.As a leading exporter of construction machinery parts, {Company Name} has built a strong reputation for delivering reliable and durable products to its clients worldwide. The Dh55 and D375 bottom rollers, in particular, have garnered significant attention for their performance and durability in the field. These rollers play a critical role in the smooth operation of heavy machinery, and {Company Name} has become a trusted source for these essential components.With the expansion of its export capabilities for Dh55 and D375 bottom rollers, {Company Name} is aiming to reach new markets and meet the growing demand for these products. By strengthening its distribution network and streamlining its logistics operations, the company is poised to enhance its ability to deliver its products to customers in a timely and efficient manner. This will not only benefit the company's bottom line but also enable it to better serve its clients and support their ongoing projects.In addition to its export expansion, {Company Name} is also increasing its production capacity for D375 heavy wheels. As an OEM factory for these critical components, the company is dedicated to meeting the needs of its clients in the construction and heavy machinery industries. The D375 heavy wheels are designed to withstand tough working conditions and provide exceptional performance in the field. With the rise in construction and infrastructure projects around the world, the demand for these heavy wheels has grown significantly, prompting {Company Name} to invest in expanding its manufacturing capabilities.By ramping up its production of D375 heavy wheels, {Company Name} is positioning itself to meet the current and future demands of its clients. The company's focus on quality and precision in its manufacturing processes ensures that its heavy wheels meet the highest standards and provide reliable performance in the field. This commitment to excellence has earned {Company Name} the trust and loyalty of its clients, and the company is dedicated to upholding its reputation as a leading provider of heavy machinery components.The expansion of {Company Name}'s export capabilities for Dh55 and D375 bottom rollers, as well as its increased production capacity for D375 heavy wheels, reflects the company's proactive approach to meeting the needs of the market. By identifying opportunities for growth and investing in its capabilities, {Company Name} is positioning itself for continued success in the industry. The company's commitment to delivering exceptional products and services to its clients underscores its dedication to being a reliable partner in the construction and heavy machinery sectors.In conclusion, {Company Name} is set to expand its export capabilities for Dh55 and D375 bottom rollers, as well as increase its production capacity for D375 heavy wheels. By doing so, the company is poised to better serve its clients and meet the growing demand for these critical components in the global market. With a focus on quality, reliability, and customer satisfaction, {Company Name} is committed to maintaining its position as a leading provider of construction machinery parts and components.

Understanding the Importance of H-Link Rod in Automotive Suspension Systems

H-Link Rod, a critical component in the automotive industry, has recently gained widespread attention due to its high-quality performance and reliability. As a leading supplier of automotive parts, {} has been making significant strides in the industry by providing top-notch H-Link rods that meet the highest standards of durability and performance. The H-Link rod, also known as the sway bar link, plays a crucial role in the suspension system of a vehicle. It connects the sway bar to the suspension control arm, helping to stabilize the car during cornering and rough road conditions. A high-quality H-Link rod is essential for ensuring smooth and safe driving experience, which is why automotive manufacturers and consumers alike rely on {} for their H-Link rod needs.With a strong commitment to quality and innovation, {} has been at the forefront of producing advanced H-Link rods that exceed industry standards. The company's dedication to research and development has led to the creation of H-Link rods that are not only durable and reliable but also highly efficient in improving vehicle performance and handling.{}'s H-Link rods are manufactured using the latest technologies and materials, ensuring that they are able to withstand the rigors of everyday driving. The company's stringent quality control measures guarantee that each H-Link rod meets the highest standards of performance and reliability, providing customers with a peace of mind knowing that they are utilizing a top-tier product.In addition to their exceptional quality, {}'s H-Link rods are also designed to be easy to install, making them an ideal choice for both automotive manufacturers and aftermarket customers. The company's commitment to customer satisfaction extends beyond the quality of their products, as they also offer excellent customer support and assistance to ensure that their clients have a positive experience with their H-Link rod purchases.Furthermore, {} is dedicated to sustainability and environmental responsibility, ensuring that their manufacturing processes are eco-friendly and adhere to the highest environmental standards. This commitment to sustainability is reflected in the company's H-Link rods, which are designed to be long-lasting and recyclable, reducing the environmental impact of automotive waste.With an unwavering dedication to excellence and a focus on continuous improvement, {} has solidified its position as a trusted supplier of H-Link rods in the automotive industry. Through their relentless pursuit of quality and innovation, the company has established itself as a leader in the production of high-performance automotive parts, with their H-Link rods being a testament to their commitment to excellence.As the demand for high-quality automotive parts continues to grow, {} remains at the forefront of the industry, setting the standard for H-Link rods and other critical components. With their unparalleled dedication to quality, innovation, and sustainability, {} is poised to continue making significant contributions to the automotive industry for years to come.

Top quality undercarriage parts for a powerful bulldozer!

Title: Renowned Construction Equipment Manufacturer Komatsu Introduces Cutting-Edge D375 Bulldozer Undercarriage PartsIntroduction:Komatsu, a globally acclaimed leader in manufacturing construction and mining equipment, has once again made a significant breakthrough in the industry. With an unwavering commitment to engineering excellence and customer satisfaction, Komatsu has recently unveiled an innovative range of undercarriage parts for their highly popular D375 bulldozer. The introduction of these cutting-edge components marks a new era in heavy machinery, promising enhanced durability, productivity, and efficiency for construction professionals worldwide.Unveiling the Revolutionary Undercarriage Parts:The latest undercarriage parts for the Komatsu D375 bulldozer are a result of years of rigorous research and development. Focusing on addressing the specific needs and challenges faced by the construction industry, these components offer numerous notable improvements in performance, reliability, and longevity.1. Enhanced Durability:Komatsu's engineers have designed the undercarriage system with reinforced heavy-duty materials, ensuring superior strength and resilience. This advancement enables the D375 bulldozer to endure extreme conditions and demanding terrains, reducing downtime and maintenance costs.2. Improved Traction and Stability:The new undercarriage parts feature optimized track shoes, providing increased traction and stability. This advancement allows the D375 bulldozer to navigate challenging terrains with ease, enhancing overall productivity and efficiency.3. Advanced Lubrication System:Understanding the importance of proper lubrication in minimizing wear and tear, Komatsu has introduced an advanced lubrication system for the undercarriage parts. This system ensures reliable and consistent lubrication throughout operation, extending the lifespan of the components and lowering maintenance frequency.4. Easy Maintenance and Serviceability:Komatsu has gone above and beyond to design the undercarriage parts for convenient maintenance and hassle-free servicing. With easily accessible components and simplified assembly/disassembly processes, construction professionals can save time and effort on routine inspections and repairs.Unmatched Commitment to Quality and Customer Satisfaction:As a globally recognized leader in construction equipment, Komatsu takes pride in offering not just cutting-edge technology but also exceptional customer satisfaction. All undercarriage parts are rigorously tested to meet the highest quality standards, guaranteeing longevity and value for money. Furthermore, Komatsu's extensive worldwide network ensures readily available aftermarket support, comprehensive training, and expert assistance for any queries or concerns regarding these innovative components.The Impact on the Construction Industry:The introduction of the revolutionary undercarriage parts for the Komatsu D375 bulldozer promises to redefine productivity and efficiency in the construction sector. With enhanced durability, improved traction, and advanced lubrication systems, construction professionals will experience smoother and more efficient operations, leading to reduced downtime and increased project completion rates. The new components also highlight Komatsu's commitment to sustainable practices, as their extended lifespan reduces the environmental impact associated with frequent replacement of worn-out parts.Conclusion:Komatsu's unveiling of the advanced undercarriage parts for the D375 bulldozer reinforces the company's commitment to innovation and engineering excellence. Designed to withstand the rigors of demanding construction environments, these revolutionary components ensure enhanced durability, performance, and efficiency. Komatsu's unwavering dedication to customer satisfaction and their global support network further solidify their position as a world leader in the construction and mining equipment industry. With the introduction of these groundbreaking undercarriage parts, Komatsu continues to empower construction professionals with the tools they need to build a better future.

Discover the Benefits of Heavy Duty Track Rollers in China

China Heavy Duty Track Roller Company, a leading manufacturer in the construction equipment industry, announced the launch of their latest track roller product. The new track roller is designed to provide superior performance and durability, making it ideal for heavy-duty construction and earthmoving machinery.The company, with over 20 years of experience in the industry, is known for its high-quality products and commitment to innovation. They specialize in manufacturing track rollers for a wide range of construction equipment, including excavators, bulldozers, and compact track loaders.The newly launched track roller is the result of extensive research and development, aimed at meeting the demands of the construction industry for reliable and long-lasting components. It is manufactured using advanced technology and high-quality materials to ensure maximum strength and resistance to wear and tear.The track roller features a robust design that is capable of withstanding the heavy loads and harsh working conditions commonly encountered in construction and earthmoving applications. It is also engineered to deliver smooth operation and minimal friction, resulting in reduced wear on the equipment and lower maintenance costs.In addition to its superior performance, the track roller is designed for easy installation and maintenance, allowing construction equipment operators to maximize their productivity and minimize downtime. This is a critical advantage in the construction industry, where time is of the essence and any equipment failure can result in costly delays.The company's dedication to quality and customer satisfaction is reflected in the rigorous testing and quality control measures applied to each track roller before it leaves the manufacturing facility. This ensures that customers receive a product that meets the highest standards and delivers consistent performance in the field.With the launch of the new track roller, China Heavy Duty Track Roller Company further solidifies its position as a trusted partner for construction equipment manufacturers and contractors around the world. The company's track record of delivering reliable and durable components has earned them a strong reputation in the industry, and the new product is expected to further enhance their standing."We are excited to introduce our latest track roller, which represents the next step in our commitment to providing the best solutions for the construction equipment industry," said a spokesperson for China Heavy Duty Track Roller Company. "We believe that our new track roller will set a new standard for performance and durability, and we are confident that it will meet the needs of our customers in a wide range of applications."As the construction industry continues to evolve and demand for heavy-duty equipment remains strong, China Heavy Duty Track Roller Company is poised to play a key role in meeting the needs of this dynamic sector. The company's focus on innovation and quality, combined with its deep expertise in manufacturing construction equipment components, positions it well for continued success in the years to come.The launch of the new track roller is a testament to China Heavy Duty Track Roller Company's ongoing commitment to excellence and their determination to provide cutting-edge solutions for the construction industry. As the demand for reliable and durable track rollers continues to grow, the company is well-positioned to meet this need and to further expand its presence in the global market.

Quality Dozer Parts for International Machinery

press release.International Dozer Parts, a leading supplier of high-quality aftermarket parts for heavy equipment, is pleased to announce the expansion of their product line to include a wider range of replacement parts for dozers. With this expansion, International Dozer Parts aims to meet the growing demands of their customers and provide even more comprehensive solutions for their heavy equipment needs.Since its inception, International Dozer Parts has been dedicated to providing top-notch aftermarket parts for a variety of heavy equipment, including dozers, excavators, and loaders. The company has built a solid reputation for delivering reliable and cost-effective replacement parts that offer exceptional performance and durability."We are excited to expand our product line to include a wider range of replacement parts for dozers," said John Smith, CEO of International Dozer Parts. "This expansion is a testament to our commitment to meeting the evolving needs of our customers and our dedication to providing the highest quality aftermarket parts for heavy equipment."With the expansion of their product line, International Dozer Parts now offers a comprehensive selection of replacement parts for dozers, including track chains, rollers, idlers, sprockets, and more. These parts are designed to fit a variety of dozer models, making it easier for customers to find the exact replacement parts they need for their specific equipment.In addition to offering a wider range of replacement parts for dozers, International Dozer Parts also prides itself on providing exceptional customer service and support. The company's team of experienced and knowledgeable professionals is always on hand to assist customers with finding the right parts for their equipment and answering any questions they may have."We understand the importance of keeping heavy equipment running smoothly and efficiently, which is why we are committed to providing our customers with the highest quality aftermarket parts and exceptional customer service," said Smith. "We want our customers to have the peace of mind knowing that they can rely on us for all of their replacement part needs."As part of their commitment to quality and customer satisfaction, International Dozer Parts ensures that all of their replacement parts are manufactured to the highest standards. The company works closely with trusted suppliers to source top-grade materials and employs stringent quality control measures to ensure that every part meets their exacting standards.With their expanded product line and unwavering commitment to quality and customer satisfaction, International Dozer Parts is well-positioned to meet the needs of customers in the heavy equipment industry. As the demand for aftermarket replacement parts continues to grow, the company remains dedicated to providing the best possible solutions for keeping heavy equipment running smoothly and efficiently.For more information about International Dozer Parts and their comprehensive selection of aftermarket replacement parts for heavy equipment, please visit their website or contact their customer service team.About International Dozer Parts:International Dozer Parts is a leading supplier of aftermarket replacement parts for heavy equipment, including dozers, excavators, and loaders. The company is dedicated to providing top-quality parts that offer exceptional performance and durability, as well as exceptional customer service and support. With their expanded product line, International Dozer Parts aims to meet the evolving needs of their customers and continue to be a trusted source for aftermarket replacement parts for heavy equipment.

Ultimate Guide to Roller Track Flow Rail Systems

Roller Track Flow Rail System Revolutionizes Warehouse EfficiencyIn today's fast-paced world of e-commerce and on-demand delivery, efficient warehouse management is more important than ever. Companies are constantly seeking ways to streamline their operations, increase productivity, and ultimately, improve customer satisfaction. One revolutionary solution that is gaining traction in the industry is the Roller Track Flow Rail system, a cutting-edge technology that has the potential to transform the way warehouses operate.The Roller Track Flow Rail system is a gravity-fed warehouse storage solution that utilizes a series of rollers to create a dynamic flow rail. This system allows for the seamless movement of products within the warehouse, reducing the need for manual handling and maximizing storage density. The result is a more efficient and organized warehouse, with improved picking and replenishment processes.One company at the forefront of this innovation is [Company Name], a leading provider of warehouse automation solutions. With their expertise in material handling and storage systems, [Company Name] has successfully implemented the Roller Track Flow Rail system in numerous warehouses, delivering impressive results for their clients. The company's dedication to innovation and customer satisfaction has cemented their reputation as a trusted partner for businesses looking to optimize their warehouse operations.The Roller Track Flow Rail system offers several key benefits that make it an attractive solution for warehouse managers. Its gravity-fed design ensures a continuous and smooth flow of products, reducing the risk of bottlenecks and improving overall workflow. By eliminating the need for forklifts and other manual handling equipment, the system also contributes to a safer work environment and reduces operational costs.In addition, the Roller Track Flow Rail system allows for better utilization of available space within the warehouse. Its high storage density and efficient product flow enable businesses to maximize their storage capacity without sacrificing accessibility. This is particularly advantageous for companies operating in high-demand industries such as e-commerce and retail, where rapid order fulfillment is essential.Furthermore, the Roller Track Flow Rail system is highly adaptable and customizable, making it suitable for a wide range of products and storage requirements. Whether handling small items or large, heavy products, the system can be tailored to meet the specific needs of each warehouse, providing a flexible and scalable solution for businesses of all sizes.One of the key strengths of the Roller Track Flow Rail system is its ability to enhance the efficiency of picking and replenishment processes. The continuous flow of products ensures that items are easily accessible and visible, facilitating faster and more accurate picking operations. This leads to reduced lead times and improved order fulfillment rates, ultimately benefiting both the warehouse and its customers.With its proven track record of success, the Roller Track Flow Rail system has emerged as a game-changer in the field of warehouse management. Its ability to increase productivity, optimize storage space, and improve workflow has made it an invaluable asset for businesses striving to stay competitive in today's dynamic market.As the demand for efficient warehouse solutions continues to grow, companies like [Company Name] are poised to play a pivotal role in driving industry innovation. By leveraging cutting-edge technologies such as the Roller Track Flow Rail system, these companies are empowering businesses to achieve new levels of efficiency and performance in their operations.In conclusion, the Roller Track Flow Rail system represents a significant advancement in warehouse management, offering a range of benefits that have the potential to transform the way businesses operate. With the support of forward-thinking companies like [Company Name], this innovative technology is set to shape the future of warehouse automation and drive continued improvements in the industry.

Durable Wear Parts for Excavator Buckets: A Complete Guide

Bucket Wear Parts Company, a leading provider of wear parts for heavy machinery in the construction and mining industries, has recently announced the launch of its new product line designed to improve the performance and longevity of excavator and loader buckets. With a focus on innovation and quality, the company aims to revolutionize the wear parts market with its advanced product offerings.Established in 2008, Bucket Wear Parts Company has quickly become a trusted name in the industry, known for its durable and high-performance wear parts. The company's products are designed to withstand the toughest working conditions, providing exceptional value for customers who rely on their heavy machinery for their daily operations."We are committed to providing our customers with the best possible solutions for their wear part needs," said the company's CEO. "With the launch of our new product line, we are raising the bar for performance and durability in the industry."The new product line includes a range of cutting edges, bucket teeth, and wear plates, all made from high-quality materials and engineered to deliver superior wear resistance and strength. The company has invested heavily in research and development to ensure that its products meet the highest standards for quality and performance."We understand the importance of reliable wear parts in maximizing the productivity of heavy machinery," the CEO added. "That's why we have spared no expense in developing our new product line, which we believe will set a new standard for excellence in the industry."The company's dedication to quality is reflected in its state-of-the-art manufacturing facilities, where advanced technology and precision engineering are employed to produce wear parts that meet the most demanding specifications. Additionally, the company's team of skilled engineers and technicians are constantly working to innovate and improve its product offerings."We take pride in our ability to deliver custom solutions to meet the unique needs of our customers," said the CEO. "Whether it's a specific material requirement or a special design consideration, our team is dedicated to finding the best possible solution for every customer."With a global presence, Bucket Wear Parts Company serves a diverse customer base, including construction companies, mining operations, and heavy equipment rental businesses. The company's commitment to excellence has earned it a strong reputation for reliability and customer satisfaction."We are continuously striving to exceed our customers' expectations," the CEO emphasized. "By providing top-quality wear parts and exceptional customer service, we aim to build lasting partnerships with our customers and contribute to their success."In addition to its new product line, Bucket Wear Parts Company offers a comprehensive range of wear parts for all major brands of excavators, loaders, and bulldozers. The company also provides custom fabrication services for customers with unique requirements, ensuring that they can find the perfect solution for their specific needs.As Bucket Wear Parts Company continues to grow and expand its product offerings, it remains committed to its core values of quality, innovation, and customer satisfaction. With a focus on meeting the evolving needs of the industry, the company is well-positioned to lead the way in providing wear parts that deliver exceptional performance and value for its customers."We are excited about the opportunities that lie ahead," the CEO concluded. "We will continue to push the boundaries of what is possible in the wear parts market, and we look forward to serving our customers with the best products and services available.