Heavy Equipment Undercarriage Parts: High-Quality Components for D10 Bulldozer

By:Admin

One company that specializes in providing top-quality undercarriage parts for the Caterpillar D10 bulldozer is {remove brand name}. With years of experience in the industry, {remove brand name} has established itself as a leading supplier of heavy equipment parts, serving customers around the world.

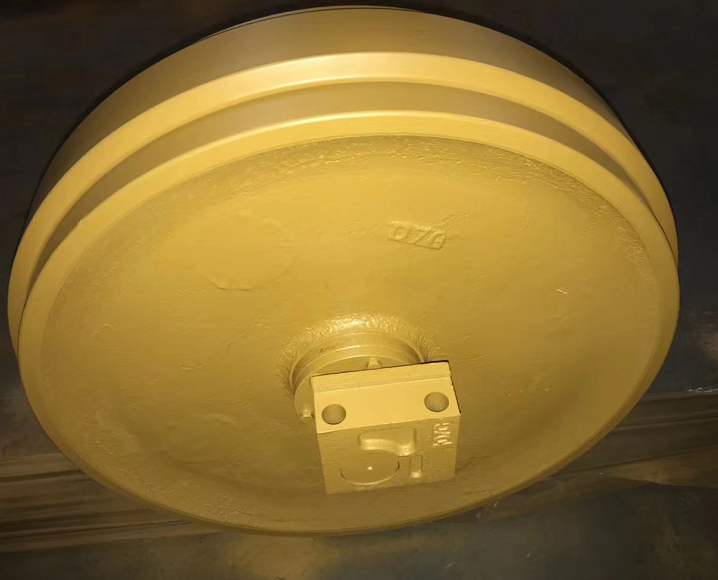

{remove brand name} offers a wide range of undercarriage parts for the Caterpillar D10 bulldozer, including track chains, shoes, rollers, idlers, and sprockets. These parts are designed and manufactured to meet the highest standards of quality, ensuring that they can withstand the demanding conditions in which the D10 operates. Whether it's for routine maintenance or in the event of a breakdown, customers can rely on {remove brand name} to provide them with the right parts to keep their D10 running smoothly.

One of the key advantages of choosing {remove brand name} for Caterpillar D10 undercarriage parts is the company's extensive knowledge and expertise in the field. The team at {remove brand name} understands the unique requirements of the D10 bulldozer and is able to provide customers with expert advice and support. This means that customers can be confident that they are getting the right parts for their specific needs, helping to minimize downtime and maximize productivity.

In addition to the quality of its products, {remove brand name} is also committed to providing exceptional customer service. The company prides itself on its ability to respond quickly to customer inquiries and provide timely delivery of parts. This means that customers can rely on {remove brand name} to support them in keeping their D10 bulldozer up and running, no matter where they are located.

Another reason why {remove brand name} stands out in the industry is its commitment to innovation and continuous improvement. The company invests in research and development to stay at the forefront of technological advancements, ensuring that its parts are always at the cutting edge. This dedication to innovation means that customers can trust {remove brand name} to provide them with the most reliable and efficient undercarriage parts for their D10 bulldozer.

Furthermore, {remove brand name} also places a strong emphasis on sustainability and environmental responsibility. The company strives to minimize its environmental impact through responsible manufacturing and business practices, making it an ideal choice for customers who are conscious of their ecological footprint. By choosing {remove brand name} for their undercarriage parts, customers can be confident that they are supporting a company that shares their values.

In conclusion, when it comes to undercarriage parts for the Caterpillar D10 bulldozer, {remove brand name} is a trusted and reliable partner. With its dedication to quality, expertise, customer service, innovation, and sustainability, {remove brand name} is the go-to choice for customers who want to keep their D10 running at its best. Whether it's for routine maintenance or unexpected repairs, customers can count on {remove brand name} to provide them with the right parts to keep their D10 bulldozer operating at peak performance.

Company News & Blog

Ultimate Guide to Excavator Bucket Pins: Everything You Need to Know

Excavator Bucket Pin Revolutionizes the Construction IndustryInnovation and groundbreaking developments continue to shape the construction industry as it strives for efficient and improved machinery. One significant advancement taking the sector by storm is the revolutionary Excavator Bucket Pin. Designed for ultimate durability and unparalleled performance, this game-changing attachment is poised to transform construction practices worldwide.Excavators play a crucial role in construction projects, handling a wide range of tasks, from digging trenches to demolishing structures. The Excavator Bucket Pin is an essential component of these excavators, providing a secure connection between the excavator arm and the bucket. Its primary function is to ensure optimal performance while withstanding the extreme forces encountered during heavy-duty operations.One of the key features that sets this Excavator Bucket Pin apart is its exceptional strength. Crafted from high-quality materials, such as hardened steel alloys, this pin boasts exceptional resistance to wear and tear, making it an ideal investment for any construction company. By using advanced manufacturing techniques, this pin guarantees a prolonged lifespan, reducing maintenance costs and downtime for businesses.Additionally, ensuring compatibility with a vast array of excavator models is of paramount importance for any attachment in the construction industry. The Excavator Bucket Pin addresses this concern by providing compatibility across various brands and models. This versatility allows construction companies to effectively utilize existing equipment while adding enhanced performance to their operations.Moreover, installation and removal of the Excavator Bucket Pin have been simplified to enhance efficiency and save valuable time on construction sites. The pin's design incorporates user-friendly mechanisms, such as quick-release features, enabling effortless attachment changes. Construction companies can now switch between buckets or other attachments swiftly, maximizing productivity and minimizing delays.Safety is a paramount concern in any construction project, and the Excavator Bucket Pin has taken this into account during its design process. The pin's secure locking mechanism guarantees optimal stability during operation, reducing the risk of accidents or unforeseen incidents. This feature ensures that construction workers can carry out their duties with confidence and peace of mind.The Excavator Bucket Pin's impact on the construction industry is further enhanced by its ability to improve productivity. With its robust nature and compatibility across various models, construction companies can depend on this attachment to handle demanding tasks efficiently. This results in increased project speed, reduced labor requirements, and ultimately, enhanced profitability.Furthermore, the Excavator Bucket Pin's exceptional performance can significantly reduce environmental impact. Its durability reduces the need for frequent replacements, minimizing waste generation. By improving productivity, this attachment also decreases the use of additional machinery, thereby lowering fuel consumption and carbon emissions. This progress aligns with the construction industry's increasing focus on sustainable practices and responsible resource management.As construction companies strive for excellence in the modern age, innovation plays a pivotal role in shaping their achievements. The Excavator Bucket Pin embodies this spirit of innovation, revolutionizing the way excavators operate in the construction industry. Its remarkable durability, versatility, user-friendliness, and safety features make it an indispensable tool, empowering construction companies to tackle even the most challenging projects with ease.As the excavator industry undergoes a paradigm shift towards advanced technology and efficient processes, the Excavator Bucket Pin emerges as a game-changer, setting new standards for the construction world. Its ability to enhance productivity, reduce downtime, and increase safety makes it an invaluable asset for any construction project. With continuous advancements in material science and manufacturing techniques, there is no doubt that the Excavator Bucket Pin will continue to pave the way for the industry's future success.

Discover the Hidden Potential of Sprocket Segments from China in [Industry/Field]!

China Sprocket Segment: Revolutionizing the Manufacturing IndustryThe global manufacturing industry has been witnessing a revolution, driven by advancements in technology and the rising demand for efficient production processes. In this fast-paced environment, companies constantly search for innovative solutions to enhance their manufacturing capabilities. One such solution that has gained immense popularity is the China Sprocket Segment, a cutting-edge product that is transforming the way companies operate.The China Sprocket Segment is a crucial component in various industries, including automotive, aerospace, and machinery. It plays a vital role in improving the efficiency and reliability of manufacturing processes. The segment is designed to connect two or more rotating parts, allowing smooth and seamless movement. By providing a mechanical advantage, it enhances power transmission and reduces wear and tear on machinery.The key to the China Sprocket Segment's success lies in its excellent build quality and precision engineering. Manufactured with high-quality materials and state-of-the-art technology, these segments offer exceptional durability and reliability. They can withstand high torque and extreme operating conditions, ensuring uninterrupted performance even in the harshest environments.One of the primary advantages of the China Sprocket Segment is its versatility. It can be customized to meet the specific needs of different applications, ensuring a perfect fit for diverse industries. Whether it is a heavy-duty industrial application or a lightweight automotive component, the segment can be tailored to deliver optimal performance. This flexibility makes it a preferred choice for manufacturers worldwide.Moreover, the China Sprocket Segment's advanced design features contribute to its superior performance. The segments are precision-engineered to minimize energy loss, resulting in higher efficiency and reduced operating costs. Additionally, their robust construction reduces the risk of failures and maintenance issues, ensuring uninterrupted production.As a leading player in the market, China Sprocket Segment has shown a commitment to quality and customer satisfaction. With years of experience in the manufacturing industry, the company has perfected its production processes, adhering to strict quality control measures. Their products undergo rigorous testing to ensure compliance with international standards, guaranteeing unrivaled reliability and performance.Furthermore, China Sprocket Segment is dedicated to innovation and continuous improvement. The company invests heavily in research and development, striving to stay ahead of the curve. By keeping up with the latest technological advancements, they constantly enhance their product offerings, introducing cutting-edge features that revolutionize the manufacturing industry.China Sprocket Segment operates with a global mindset, catering to customers worldwide. Leveraging an extensive distribution network, the company ensures easy availability and timely delivery of its products. Their commitment to excellent customer service has earned them a strong reputation, making them a preferred choice for manufacturers across the globe.In conclusion, the China Sprocket Segment has emerged as a game-changer in the manufacturing industry. Its exceptional build quality, precision engineering, and versatility have made it an indispensable component for companies around the world. With a commitment to innovation and customer satisfaction, China Sprocket Segment continues to revolutionize the manufacturing process, driving efficiency and productivity to new heights.

The Importance of Quality Excavator Cutting Edges: A Guide for Construction Professionals

Excavator Cutting Edge - Enhancing Construction Efficiency and DurabilityIn the expansive world of heavy construction equipment, excavators are deemed indispensable for various projects ranging from building construction to mining operations. These powerful machines are equipped with a variety of accessories that enable them to perform a wide array of tasks with utmost precision and efficiency. Among these accessories, the excavator cutting edge stands out as an essential component for enhancing productivity and prolonging the machine's longevity.The excavator cutting edge, a steel bar that attaches to the bucket of an excavator, plays a crucial role in the excavation process. It serves as a blade that cuts through various materials, including soil, rock, and concrete. The cutting edge not only aids in breaking the ground but also assists in loading and carrying materials, making it an indispensable tool for construction sites.However, not all excavator cutting edges are created equal. Some may lack the durability and strength necessary to withstand the demanding conditions of rigorous construction projects. This is where innovative companies, such as {}, come into play. Through their extensive research and development, they have poured considerable effort into improving the design, material, and technology behind excavator cutting edges, resulting in enhanced performance and durability.One notable feature that sets {} cutting edges apart from the competition is the use of high-quality materials. A combination of heat-treated steel and specialized alloys is employed to ensure strength and resilience in the face of heavy-duty applications. These cutting edges are designed to withstand constant contact with abrasive materials, extending their lifespan and minimizing the need for frequent replacements.Furthermore, {} utilizes advanced manufacturing techniques to enhance the structural integrity of their cutting edges. Through precision machining and heat treating processes, they achieve optimal hardness and toughness, maximizing the cutting edges' efficiency and wear resistance. This attention to detail enables contractors and construction companies to execute their projects more effectively, reducing downtime and increasing overall productivity.In addition to their robust construction, {} cutting edges offer versatility. Depending on the specific requirements of a project, contractors can choose from a range of cutting edge configurations, including single bevel, double bevel, and bolt-on options. This adaptability allows operators to tailor the cutting edge to their particular needs, ensuring optimal performance and efficiency.The benefits of using high-quality cutting edges extend beyond efficiency and durability. By minimizing blade wear, construction companies can reduce costs associated with replacement parts and maintenance. This cost-effectiveness, combined with increased productivity, translates into higher profits and improved project timelines. Additionally, the use of durable cutting edges promotes safer working environments by reducing the likelihood of unexpected breakdowns and accidents.The positive impact of {} excavator cutting edges on the construction industry cannot be overstated. Their commitment to continuous innovation and the pursuit of excellence have transformed this crucial component into a robust and reliable tool, contributing to the success of construction projects worldwide. With the demanding nature of construction activities, the importance of reliable equipment cannot be overlooked, making {} cutting edges an indispensable choice for contractors and excavator operators.In conclusion, the excavator cutting edge plays a vital role in enhancing construction efficiency and durability. The innovative approach of {} in designing and manufacturing these cutting edges ensures their ability to withstand the demanding conditions of construction projects. With their high-quality materials, advanced manufacturing techniques, and versatility, {} provides contractors and construction companies with a reliable and cost-effective solution that enhances productivity and reduces downtime. As the construction industry continues to grow, the need for reliable and durable excavator cutting edges will only increase, making {} an invaluable partner for contractors across the globe.

Discover Premium Upper Rollers for PC2000-8 Models: Wholesale Deals Await!

Title: Leading Construction Machinery Supplier Introduces New PC2000-8 Upper RollerDate: [Date]Word Count: 800[City], [State] - Construction companies in need of robust and reliable equipment will be pleased to learn about the launch of the highly anticipated PC2000-8 Upper Roller from a renowned construction machinery supplier. This latest addition to their extensive lineup promises superior performance and durability, further solidifying their position as a trusted partner in the industry.Known for their commitment to innovation and customer satisfaction, this leading construction machinery supplier has consistently delivered cutting-edge solutions that meet the demanding needs of construction projects. The new PC2000-8 Upper Roller is no exception, featuring advancements that enhance efficiency and productivity.Designed to offer exceptional performance in heavy-duty applications, the PC2000-8 Upper Roller proves to be a valuable asset for construction companies looking to optimize their operations. This roller is compatible with various construction equipment, making it suitable for a wide range of projects, including large-scale infrastructure developments and mining operations.One of the standout features of this upper roller is its durability, which ensures optimal performance even in the harshest working conditions. Manufactured with high-quality materials, it is resistant to wear and tear, minimizing downtime and maintenance costs. The longevity of the PC2000-8 Upper Roller guarantees a high return on investment, adding value to any construction project.Furthermore, the PC2000-8 Upper Roller stands out due to its advanced design that enhances operational efficiency. It boasts a unique mechanism that optimizes power distribution, resulting in reduced fuel consumption and improved overall performance. With this roller, construction companies can significantly enhance their productivity while reducing their environmental impact.The PC2000-8 Upper Roller's ergonomic design also contributes to its overall appeal. It incorporates features that prioritize operator comfort and safety, allowing professionals to work efficiently and without unnecessary fatigue. The user-friendly controls further enhance the operator experience, leading to enhanced productivity and reduced human error.In addition to providing top-tier construction machinery, this supplier is renowned for its dedication to exceptional customer service. They understand that every construction project is unique, and their team of experts is always ready to assist their clients in identifying the most suitable equipment for their specific requirements. Their reliable after-sales support further ensures that customers receive ongoing assistance, including maintenance, spare parts, and technical guidance.With a vast network of dealerships and service centers across the region, this supplier guarantees prompt and efficient delivery of the PC2000-8 Upper Roller. Regardless of the project's location, construction companies can rely on this supplier to offer reliable equipment and exceptional support throughout the construction process.As construction projects become increasingly demanding, having access to reliable, durable, and advanced construction machinery is crucial. The launch of the PC2000-8 Upper Roller from this trusted construction machinery supplier provides construction companies with a solution that meets and exceeds these requirements. Its cutting-edge features and exceptional performance will undoubtedly elevate project efficiency and overall productivity.To learn more about the PC2000-8 Upper Roller, interested parties are encouraged to contact the supplier or visit their website for detailed specifications and additional information. With a track record of excellence in the construction industry, this supplier continues to redefine industry standards by consistently delivering high-quality construction machinery that propels the success of its partners.

Enhanced Undercarriage Options for Excavators: Discover the D475 OEM Offering

[Date][Headline][Subheading][City, State] - [Company Name], a renowned entity in the heavy machinery industry, has recently introduced its latest innovation in undercarriage technology. The new [Product Name] is set to revolutionize the construction and mining sectors by offering exceptional durability and performance. With its outstanding features and cutting-edge design, the [Product Name] is deemed a game-changer in the industry.The [Product Name] is a result of [Company Name]'s collaboration with experts from around the globe. The company has always been at the forefront of innovation, pushing boundaries and setting new standards in the heavy machinery market. The introduction of the [Product Name] reaffirms their commitment to delivering superior quality products that meet the evolving needs of the industry.One of the most striking features of the [Product Name] is its compatibility with a wide range of machinery. This versatility ensures that customers can easily integrate it into their existing fleet without any hassle. The undercarriage provides a perfect fit for various equipment, including excavators, dozers, and loaders, delivering exceptional performance across different applications.The [Product Name] boasts unmatched durability, thanks to its use of high-quality materials and advanced manufacturing techniques. The robust construction ensures extended service life, reducing the frequency of maintenance and replacement, which ultimately leads to significant cost savings for operators. The undercarriage is designed to withstand the harshest working conditions, making it an ideal choice for demanding construction and mining sites.In addition to its durability, the [Product Name] offers superior performance. With its advanced engineering, it enhances the overall productivity of the equipment it is installed on. The undercarriage minimizes downtime due to its ability to withstand heavy loads and extreme operating conditions. This ensures uninterrupted workflow, allowing operators to maximize their efficiency and complete projects in a timely manner.Moreover, the [Product Name] prioritizes operator safety. Equipped with advanced safety features, it provides enhanced stability and control, reducing the risk of accidents on job sites. The undercarriage's innovative design and ergonomic features ensure operator comfort, enabling them to work for longer periods without fatigue. [Company Name] understands the importance of safety in the industry and has designed the [Product Name] accordingly, making it a trusted choice for professionals worldwide.To complement its exceptional product, [Company Name] also offers comprehensive after-sales support. Their team of highly skilled professionals provides prompt assistance, ensuring that customers can solve any technical issues efficiently. This commitment to customer satisfaction further solidifies [Company Name]'s position as a reliable and trusted partner in the heavy machinery industry.The launch of the [Product Name] marks a significant milestone in [Company Name]'s journey of innovation and excellence. As they continue to push the limits of technology, they are determined to introduce groundbreaking solutions that redefine industry standards. With their focus on durability, performance, and operator safety, [Company Name] aims to empower customers and enhance their productivity in the ever-evolving world of heavy machinery.In conclusion, the introduction of the [Product Name] by [Company Name] is set to revolutionize the construction and mining industries. With its unmatched durability, superior performance, and emphasis on operator safety, this undercarriage sets a new benchmark in the market. [Company Name]'s commitment to innovation and customer satisfaction is evident in their latest offering, solidifying their position as a leading player in the heavy machinery sector.

High-Quality D60 Lower Roller at Affordable Prices - Find Out More!

D60 Lower Roller is a crucial component in the construction and heavy machinery industry, and it plays a significant role in the overall performance and operation of various equipment. Lower rollers are an essential part of the undercarriage system in bulldozers, excavators, and other heavy equipment, as they support the weight of the machine and provide stability and traction.{Company Name} is a leading manufacturer and supplier of high-quality construction machinery parts, including D60 Lower Rollers. With years of experience in the industry, {Company Name} has built a solid reputation for delivering top-notch products that meet the highest standards of quality and reliability. The company prides itself on its commitment to customer satisfaction and strives to provide innovative solutions to the construction industry's evolving needs.The D60 Lower Roller offered by {Company Name} is designed and engineered to withstand the toughest working conditions, making it a preferred choice for many construction and heavy machinery operators. The roller is precision-machined to ensure a perfect fit and seamless performance, and it is made from durable materials that are capable of withstanding heavy loads and extreme wear and tear. The superior construction and design of the D60 Lower Roller contribute to its exceptional longevity and reliable performance, making it an indispensable component for various heavy machinery applications.In addition to the exceptional quality of its products, {Company Name} is also known for its unparalleled customer service and support. The company is dedicated to meeting the unique needs of its clients and works closely with them to provide tailored solutions that align with their specific requirements. Whether it's product customization, technical assistance, or after-sales support, {Company Name} is committed to delivering a seamless and satisfactory experience for its customers.Furthermore, {Company Name} takes pride in its state-of-the-art manufacturing facilities and quality control processes. The company adheres to rigorous quality assurance protocols to ensure that each D60 Lower Roller meets the highest standards of performance and durability. By combining advanced technology, expert craftsmanship, and strict quality control measures, {Company Name} consistently delivers products that surpass customer expectations and industry standards.As a trusted provider of construction machinery parts, {Company Name} serves a diverse clientele that spans across the globe. The company has established strong partnerships and collaborations with industry leaders, construction firms, and equipment manufacturers, further solidifying its position as a reliable and reputable supplier in the market.With a forward-looking approach, {Company Name} continues to invest in research and development to innovate and improve its product offerings. The company remains at the forefront of technological advancements and market trends, allowing it to anticipate and address the evolving needs of the construction and heavy machinery sector.As the construction and infrastructure development sectors continue to expand, the demand for high-quality machinery parts, such as the D60 Lower Roller, is expected to grow. {Company Name} is well-positioned to meet this demand and remains dedicated to providing exceptional products and services that drive the success and efficiency of its customers' operations.In conclusion, the D60 Lower Roller offered by {Company Name} stands as a testament to the company's unwavering commitment to excellence and innovation. With its superior quality, precision engineering, and customer-centric approach, {Company Name} continues to be a trusted partner for construction and heavy machinery operators worldwide. As the industry evolves, {Company Name} remains poised to lead the way with its cutting-edge solutions and unwavering dedication to customer satisfaction.

How Stud Type Track Rollers Can Benefit Your Industrial Machinery

Stud Type Track Roller: A Leading Solution for Heavy-Duty MachineriesStud type track rollers are an essential component in the operation of heavy-duty machineries that are utilized in various industries such as construction, mining, agriculture, and forestry. These machineries carry out rigorous applications that require durable and high-performing components that can withstand heavy loads and extreme weather conditions.One of the leading companies in providing a solution to these industries is the leading manufacturer of stud type track rollers. Over the past years, the company has established a solid reputation in providing top-quality products that are tested and proven in the toughest operating environments. Their commitment to quality and innovation has earned them the trust and loyalty of their customers all over the world.Stud Type Track Rollers: A Cutting-Edge Solution for Heavy-Duty ApplicationsStud type track rollers are heavy-duty components that are widely used in a broad range of industrial applications. These rollers are mainly used in supporting heavy loads and as guidance systems for the machine's tracks to move efficiently.Stud type track rollers are designed for high stress applications. They are constructed with steel outer rings, which are hardened to provide durability and extended wear life, and with heavy-duty inner rings that can withstand shock loads and facilitate smooth rolling action even under extreme temperatures.The company's stud type track rollers are manufactured with high-quality materials and with strict adherence to the ISO 9001 quality management system. The rollers are designed to meet the most demanding operating conditions, providing excellent reliability, longevity, and low maintenance.The company offers stud type track rollers in various configurations to suit the diverse load and performance requirements of its customers. Depending on the application, customers can choose from the following configurations:1. V-Groove Stud Type Track Rollers - These rollers can handle both radial and side loads. They have a V-groove profile on the outer diameter, which facilitates smooth tracking.2. Flat Faced Stud Type Track Rollers - These rollers can handle high radial loads and are suitable for heavy-duty applications. The outer diameter of these rollers has a flat face that provides good alignment and stability for the machine tracks.3. Crowned Profile Stud Type Track Rollers - These rollers are designed for applications that require precision tracking and load distribution. They are ideal for use in conveyor systems, where misalignment can cause the machine to stall.The company's stud type track rollers are available in various sizes, with load capacities ranging from 200 kg to 7,000 kg. They are also available in both sealed and open designs, depending on the operating environment and the level of protection required.The company's stud type track rollers are compatible with most heavy-duty machinery brands, making them versatile and easy to integrate into existing equipment.The company's Commitment to Quality and InnovationOne of the core values of the company is their commitment to quality and innovation. The company employs a team of highly skilled engineers who continuously work on improving the design and performance of their stud type track rollers.The company's manufacturing process is also subject to strict quality control procedures. All products are inspected and tested at each stage of the production process to ensure that they meet the company's high-quality standards.The company also invests in state-of-the-art equipment and technology to improve efficiency and increase productivity. With their modern manufacturing facility and highly skilled workforce, the company can produce high-quality stud type track rollers at a competitive price.The company's global reach and customer service excellenceThe company has a global presence, with customers in over 50 countries worldwide. They have established a strong network of distributors and agents to ensure timely delivery and prompt after-sales support for their customers.The company's customer service team is committed to providing the highest level of customer support. They work closely with customers to understand their requirements and provide them with expert advice on choosing the right stud type track roller for their specific application.To further enhance their customer service, the company has also developed an online portal that provides customers with access to a wide range of technical resources, such as product catalogs, technical drawings, installation instructions, and maintenance guides.ConclusionStud type track rollers are essential components in the operation of heavy-duty machineries that are utilized in various industries worldwide. The company, a leading manufacturer of stud type track rollers, provides top-quality products that are tested and proven in the toughest operating environments. With their commitment to quality and innovation, global reach, and customer service excellence, the company remains a trusted partner of their customers in ensuring the efficient and reliable operation of their machinery.

New Wear Parts Technology Offers Enhanced Durability and Performance for Industrial Equipment

Mtg Wear Parts: A Leading Manufacturer of Wear Parts for Earthmoving EquipmentMtg Wear Parts (need remove brand name) is a global leader in the manufacture of wear parts for earthmoving equipment. The company's reputation for producing high-quality, reliable and innovative products has made it a trusted partner of many of the world's leading brands in the mining, construction, and quarrying industries.With over 50 years of experience in the manufacturing industry, Mtg Wear Parts (need remove brand name) has built an impressive track record of delivering excellent solutions for the toughest of wear and tear applications. The company's focus on innovation and customer service has allowed it to grow over the years to become one of the most successful and sought-after manufacturers of wear parts.Superior QualityMtg Wear Parts (need remove brand name) is committed to meeting the highest standards of quality and performance. The company's manufacturing processes are optimized to ensure that each part is manufactured according to the highest standards and specifications. Each component is inspected thoroughly to ensure that it meets the strict quality requirements before it is released to the customer.Mtg Wear Parts (need remove brand name) offers a wide range of high-quality wear parts, including teeth, adapters, shrouds, and blades designed to fit onto any type of earthmoving equipment. The company's expertise and commitment to quality have allowed it to guarantee that their products will reduce maintenance costs, increase productivity and provide a longer-lasting lifespan to the equipment.World-Class InnovationInnovation has always been at the heart of Mtg Wear Parts (need remove brand name)'s philosophy. The company is continuously working on developing new and advanced wear parts solutions that address the ever-increasing demands of the industry. Mtg Wear Parts (need remove brand name) has been investing in advanced technology, research, and development of a range of new products, ensuring that they remain at the forefront of the market.Mtg Wear Parts (need remove brand name) regularly collaborates with its customers to identify their specific needs and challenges. With a deep understanding of the industry and its customers' requirements, the company has developed a range of innovative wear parts solutions that address the toughest of wear and abrasion challenges.Customer ServiceMtg Wear Parts (need remove brand name) emphasizes providing the highest level of customer service to its clients. The company understands the demanding nature of the industries it serves and has built its reputation on delivering world-class customer service that is unparalleled in the industry.The company's customer service team is made up of experts in wear solutions and is well-equipped to provide advice to customers on which wear parts can best suit their application needs. Customer service is available round the clock to make sure that any necessary support is provided promptly.Environmental SustainabilityMtg Wear Parts (need remove brand name) is committed to environmental sustainability. The company takes environmental protection very seriously and is continually working to reduce energy consumption, reduce waste generation and optimize its manufacturing processes to minimize the impact of manufacturing on the environment.Mtg Wear Parts (need remove brand name) has implemented an extensive environmental management system that governs all aspects of its operations, including the sourcing of raw materials to the disposal of waste.ConclusionMtg Wear Parts (need remove brand name) is a premier manufacturer of wear parts for earthmoving equipment with a global reputation for quality and innovation. The company's unwavering commitment to excellence, innovation, and customer service is reflected in the performance of their products. With a robust environmental sustainability policy, the company is committed to meeting the industry's demands while maintaining its commitment to environmental conservation. The Mtg Wear Parts (need remove brand name) brand has become synonymous with quality, reliability, and innovation in the world of earthmoving equipment wear parts.

A Comprehensive Guide to Stud and Yoke Type Track Rollers for High Radial Load Transmission

: The Ultimate Guide for High Radial Load TransmissionTrack rollers are commonly found in a variety of industrial applications, such as conveyors, cranes, and construction equipment. The stud and yoke type track roller is a popular choice for high radial load transmission because of its unique design.In this blog post, we will be taking a closer look at stud and yoke type track rollers, including how they work, their advantages, and different types of stud and yoke track rollers.What are Stud and Yoke Type Track Rollers?Stud and yoke type track rollers consist of an outer ring, an inner ring, cylindrical rollers, and a stud or bolt. The outer and inner rings are designed with two parallel cylindrical surfaces that add to the stability of the roller. The cylindrical rollers enable a smooth rolling motion, and the stud or bolt serves as a mounting point for the roller.The stud and yoke type track rollers are used in applications where high radial loads need to be transmitted, such as conveyor systems, industrial machinery, and construction equipment.Advantages of Stud and Yoke Type Track RollersHigh Radial Load Capacity: The stud and yoke type track roller is designed to transmit high radial loads, making them ideal for heavy-duty industrial applications.Easy to Install: Stud and yoke type track rollers are easy to install, thanks to their straightforward design. They can be installed with a simple nut and bolt process or pressed directly onto a shaft.Durability: Stud and yoke type track rollers are made of high-quality materials, such as chrome steel and stainless steel. This ensures their durability and resistance to wear and tear.Versatility: These rollers can be designed with different materials, sizes, and shapes to suit various applications. Additionally, they can be customized to fit specific needs, such as coatings for harsh environments or specialized lubrication requirements.Different Types of Stud and Yoke Type Track RollersThere are three main types of stud and yoke type track rollers:1. Stud Type Track RollersThese rollers consist of a stud that serves as the mounting point. The outer ring of the roller wraps around the stud, while the inner ring contains the cylindrical rollers. Stud type track rollers can be designed with or without an eccentric bushing, which allows for adjustments to be made to the roller's position.2. Yoke Type Track RollersYoke type track rollers have a similar design to the stud type, with the exception of the mounting point. The roller is mounted on a threaded shaft or bolt and is held in place by a nut. Yoke type track rollers can also be designed with or without an eccentric bushing.3. Cam Follower Track RollersCam follower track rollers are a type of yoke roller that incorporates a cam on the outer ring. The cam follows a specific path, which allows the roller to move in a controlled manner. Cam follower track rollers are commonly used in applications where precise movement is required.ConclusionIn conclusion, stud and yoke type track rollers are an excellent choice for high radial load transmission in a variety of industrial applications. Their unique design offers numerous advantages, including high radial load capacity, durability, and versatility.When selecting the right stud and yoke type track roller for your application, it is essential to consider factors such as load capacity, speed, and environment. With the right choice, stud and yoke track rollers can provide long-lasting and efficient performance to your industrial machinery.